The polishing problem has always been a problem that mold companies cannot solve fundamentally. Injection mold steel requires a good polishing skill to show the essential properties of the material. P...

More >>

In the heat treatment process, precision injection molding molds often deform. In order to prevent this bad phenomenon, as long as you grasp the law of deformation, analyze its causes, and use differe...

More >>

The materials generally used in sheet metal processing are galvanized steel, cold rolled steel, hot rolled steel, stainless steel, aluminum, aluminum alloy, and aluminized steel. Depending on the role...

More >>

1. Selection of mold materialsTo make precision injection molding molds, mold steel with small deformation (micro-deformed steel) is the best choice. Through the analysis of the severely deformed mold...

More >>

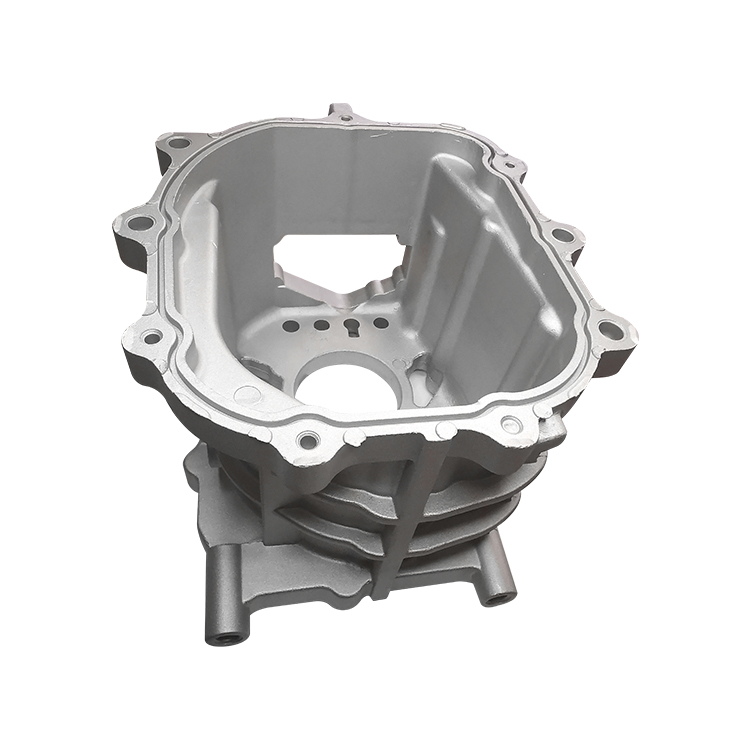

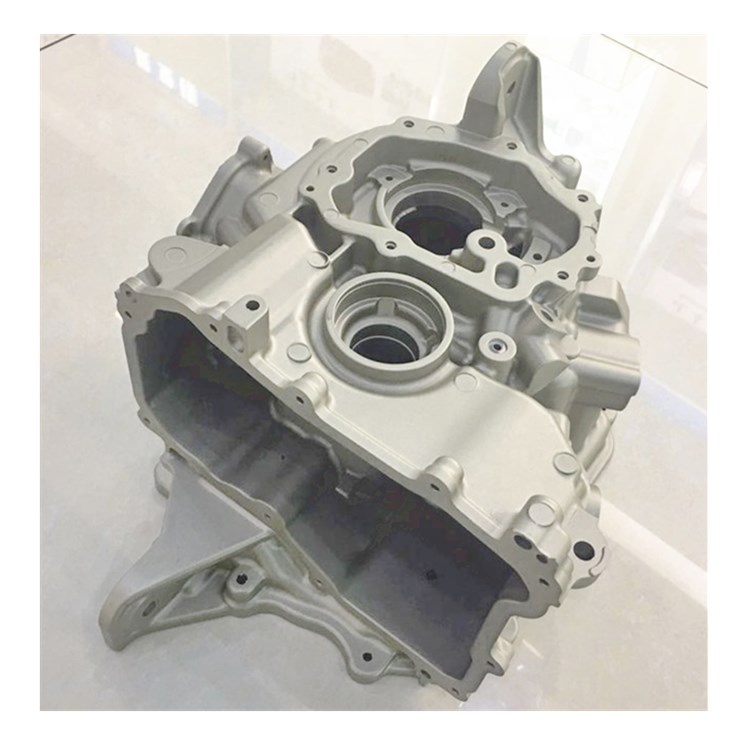

For aluminum alloy die castings, in order to improve its quality, it is necessary to increase the yield of production. Raw materials are fundamental, so it should be the top priority of the quality co...

More >>

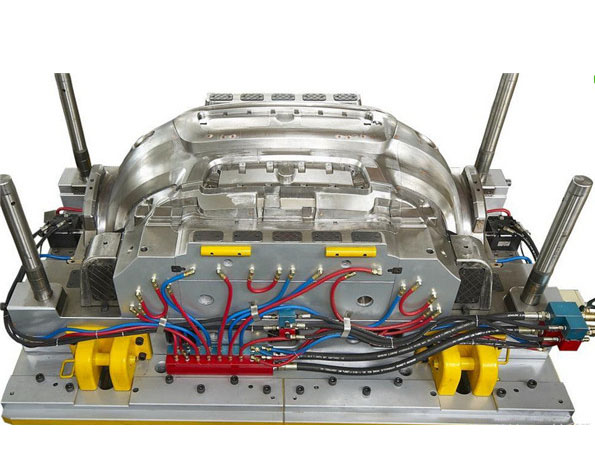

Compared with other types of molds such as stamping molds and die-casting molds, injection mold manufacturing has 5 obvious characteristics. The analysis is as follows:1. The cavity and core are three...

More >>

Die casting is a metal manufacturing process, especially suitable for manufacturing a large number of small and medium-sized castings. So die casting is the most widely used one of various casting pro...

More >>

Nowadays, when the die casting foundry are facing many challenges, the die-casting process has become an economical and effective method for manufacturing structural parts. What is the impact of globa...

More >>