Premium help customers deliver products that can exceed quality demands, we serve a wide variety of industries, including:

Lighting: LED and other light products plus die cast heat sinks, roadway lighting, area Lights and other consumer lighting components

Industrial Equipment: Aluminum die casting services for bearing housings, heat sinks and many more specific parts

Meters: Aluminum die casting services for electric, water, gas, parking and other meters

Automotive &trucking: We specialize in automotive &truck parts and systems e.g. cylinders, Engine Components

Die-cast parts weighing 4 g- 20,000 g, max size up to 1,000mm*1,000m

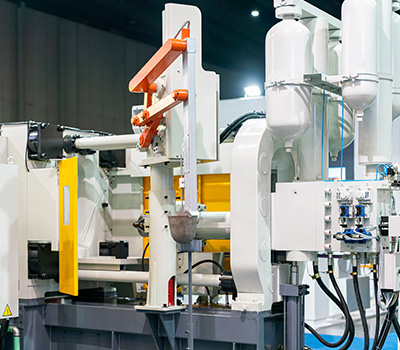

Die casting machines with up to 1850 tons clamping force

Finishing in accordance with ISO 2768-1, etc

Wide range of surface treatments available: anodizing, polishing, passivating, powder coating, chrome plating, screen printing etc

Component assembly

Name: Led Heatsink Material: ADC12 Surface Finish: Smooth |

| Name: Led light housing Material: A380 Surface Finish: Sand Blasting |

|

Name: Gearbox Housing Material: ADC12 Surface Finish: Powder coating |

| Name: Electric motor body Material: Alsi9cu3 Surface Finish: Sand blasting&Smooth |

|

Name: Pump housing Material: ADC12 Surface Finish: Shot Blasting |

| Name: valve parts Material: Aluminum Y112 Surface Finish: Shot Blasting |

|

Material | Advantages | Potential disadvantages | Remarks |

A380/ ADC10 | Lightweight Strong at high temperature Corrosion resistance Dimensional stability with complex shapes High electrical conductivity Good thermal conductivity | It is the best choice if you have budgetary concerns, and don't need the highest level of corrosion resistance and pressure density | |

A383 / ADC12 | alternatives to A380 offers improved resistance to hot cracking (strength at elevated temperatures) | Not as durable as the A380 | Typically, only used for intricate components requiring improved die filling characteristics |

A360 / ADC3 | Offers higher strength at high temperatures Better ductility Higher corrosion resistance than the A380 | Harder to cast than the A380 | |

A514 / ADC6 | Provides the best combination of strength, ductility, corrosion resistance and finishing qualities | Difficult to cast |