Magnesium alloy is with unique advantages in the manufacture of auto parts. It is a light alloy material in metal alloys with the advantages of low density, strong rigidity, good vibration, good noise...

More >>

1. The Foundry Industry Is Facing New Environmental Protection StandardsFacing the increasingly severe crisis of energy and environmental, lightweight has become an important direction in the developm...

More >>

1. Review of heat treatmentCommon heat treatment for common metal parts involves three process: annealing, normalizing and quenching. Here are some related knowledge points of the die cast aluminum al...

More >>

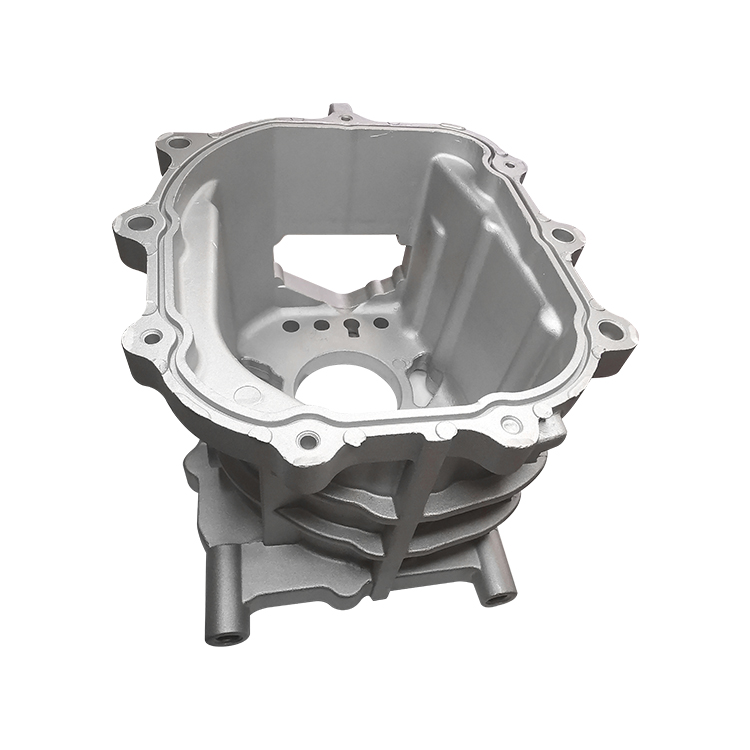

According to GB/T 5611-1998, casting (casting/founding/foundry) refers to the forming method of melting metal, making a mold, pouring the molten metal into the mold and solidifying to obtain a metal p...

More >>

Because the chemical, physical parameters and die-casting characteristics of magnesium alloys are quite different from those of aluminum alloys, the design principles of aluminum alloy die-casting mol...

More >>

Magnesium alloy can be die-casted by cold chamber or hot chamber die casting machine. The current improvements to the hot chamber die-casting machine mainly include: the use of accumulators for pressu...

More >>

What exactly is the brass casting process? What is the brass casting method? Brass casting is actually an earlier metal hot working process. The brass casting process has a history of about 6000 years...

More >>

What are sheet metal parts? Sheet metal parts are parts produced by a comprehensive cold working process for metal sheets (usually less than 6mm), including shearing, punching/cutting/compounding, fol...

More >>