As one of the most widely used methods in plastic parts manufacturing today, injection molding can facilitate large, cost-effective production runs of the same parts. In fact, in most cases, injection...

More >>We can produce a mature component by combining metal and plastic or many different metals. We sometimes regard that process as injection molding with metal inserts or metal insert molding. Insert mold...

More >>

Insert injection molding process can be an efficient alternative to assembling discrete parts using welding, connectors, fasteners, or adhesives. Compared with those ways mentioned above, the advantag...

More >>

Injection molding prototype costs vary by part and application. The mold could be thousands of dollars or hundreds of thousands of dollars. The plastic parts produced by molds may be commodities while...

More >>

Many industries rely on sheet metal manufacturing, such as aerospace, construction, automotive, electronics and energy industries. Aerospace sheet metal fabrication is a process from raw metal materia...

More >>

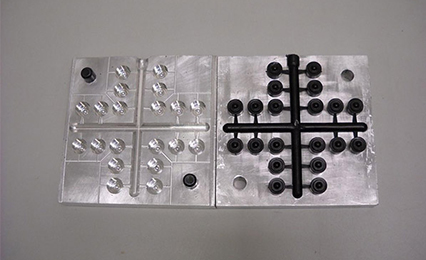

Ⅰ. Arrangement design of precision injection moldProduct arrangement is an important step in mold design. Through product arrangement, the core and cavity dimensions can be determined, and then the sp...

More >>

Sheet metal processing is just a series of processes such as bending, riveting, and welding of metal materials. The following is for the problems and solutions encountered in the bending process in sh...

More >>

In the field of laser cutting processing of metal materials, you often hear the terms sheet metal processing and high-precision sheet metal fabrication. Are they the same? What are the specific differ...

More >>