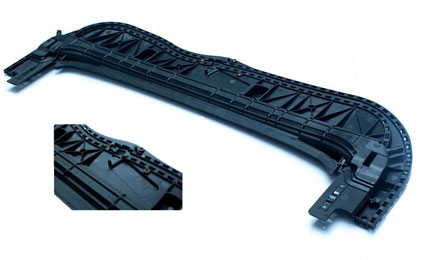

During the production of parts, accuracy and cost-effectiveness are the two most important considerations that most companies are looking for. So what kind of products are plastic injection moulding s...

More >>

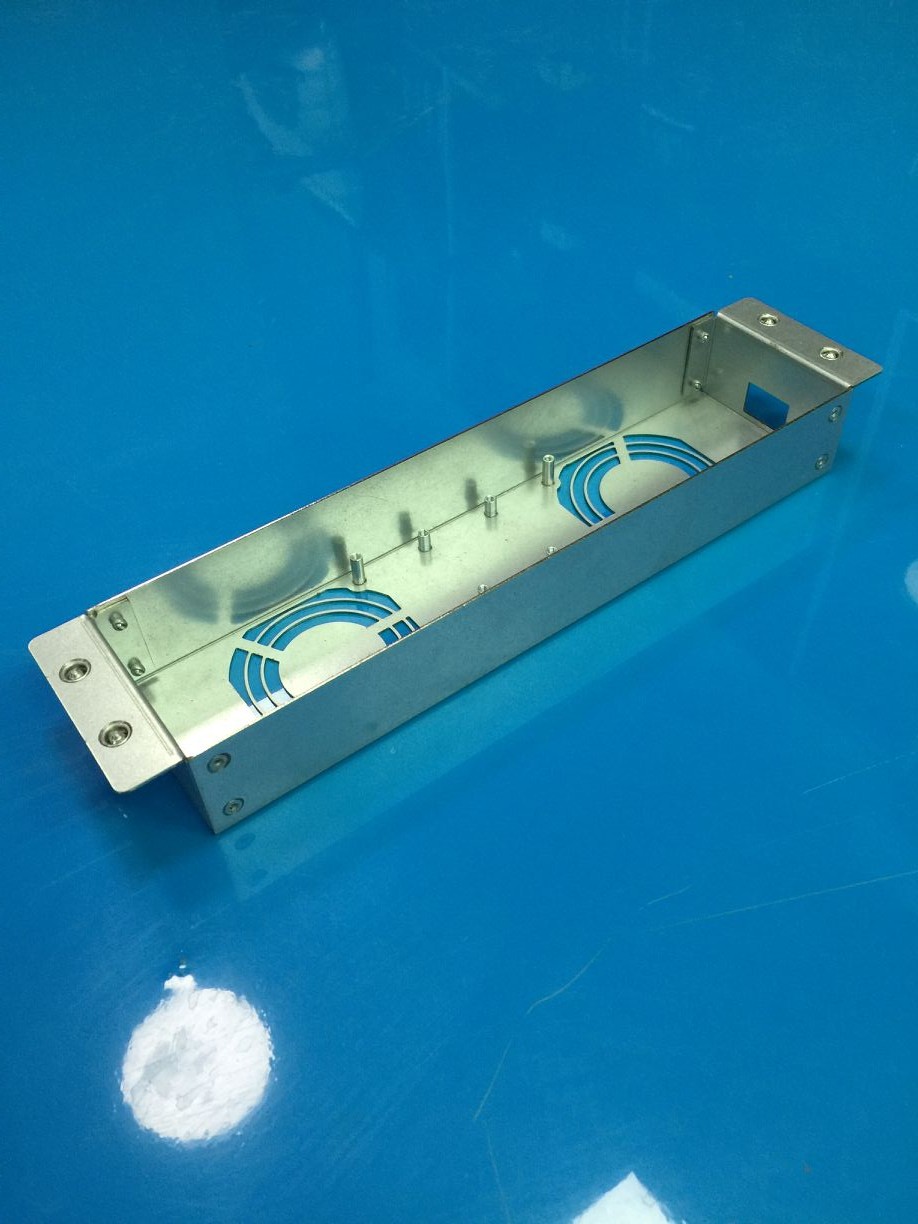

Sheet metal processing is one of the most widely used processing methods. It is made of steel, aluminum, brass, copper, tin, nickel, titanium, or precious metals. The thickness of sheet metal parts ra...

More >>

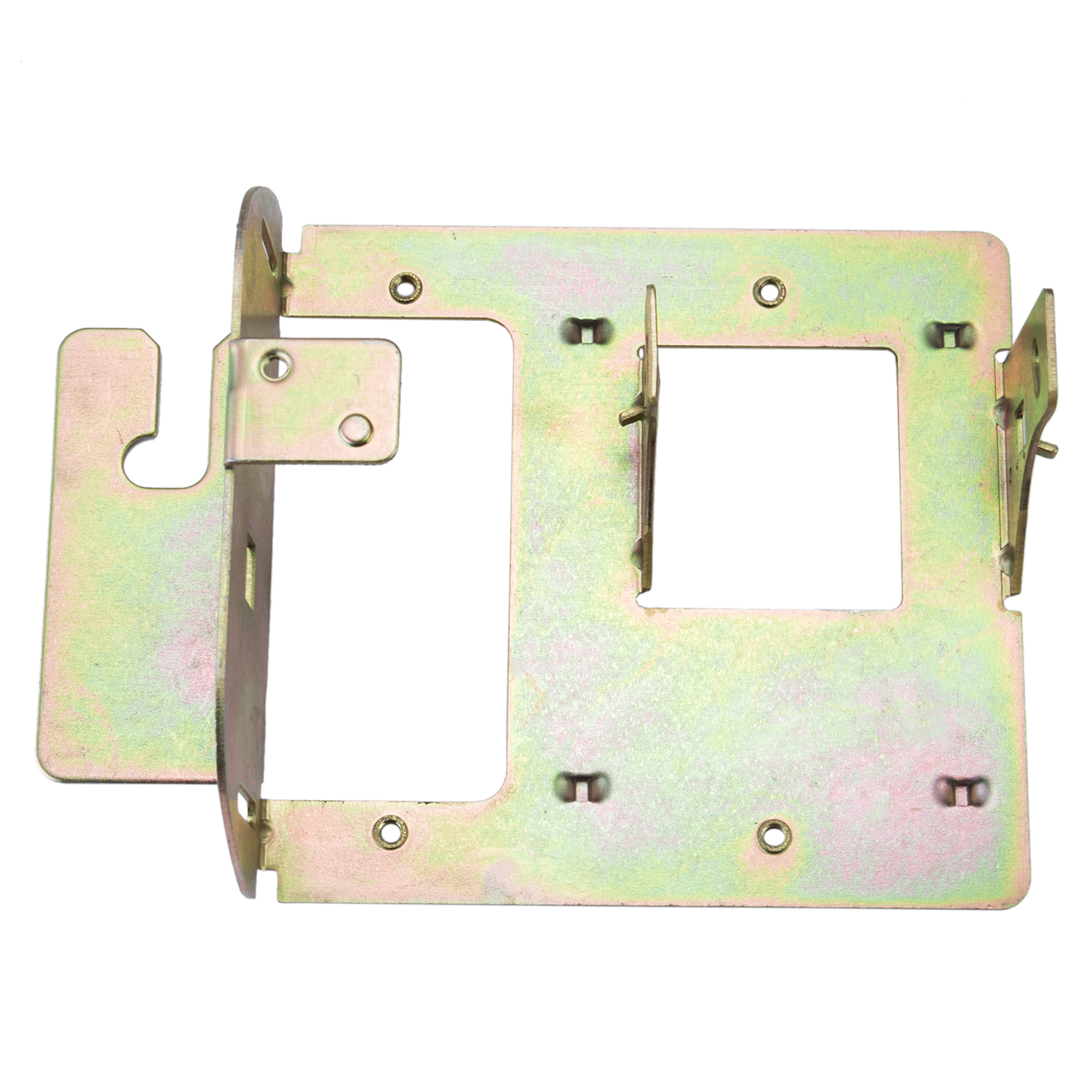

The metal stamping process is divided into bending and stretching processes, while sheet metal processing is mainly shear, bending, and welding. There are great differences in the process flow between...

More >>

In daily life, people should observe and think about important things in people's daily life. Essential items in people's daily life, such as a chimney, stainless steel barrel, gasoline barrel...

More >>

From plastic trinkets and toys to auto parts, bottles, containers to mobile phone shells, the plastic injection m process has been widely used to manufacture parts and components. In fact, many produc...

More >>

In order to meet the requirements of modern industrial development, the future sheet metal stamping parts will further develop in the direction of composite and functional. As the whole society pays m...

More >>

The sheet metal machining is a relatively common technical operation now. The reason why sheet metal machining has become so common is that it is simple and convenient compared to other processing tec...

More >>

What are the common key processes in sheet metal machining? The key processes of sheet metal machining include sheet design, drawing design, laser processing or CNC stamping dies, bending, electric we...

More >>