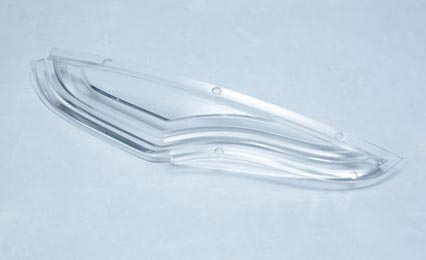

Premium precision machine inc expanded into CNC machining, sticking with our mission to improve our organization and capacities continually, currently, the max turning machine we have is 750(Length)*650mm(Diameter), the max machining machine is 1800*1600mm, below are our state of CNC machining parts:

CNC Machining Center

Turning Center

CNC Live tooling

Bar Feed Machining Cells

|

|

|

|

|

|

|

|

|

Manually cutting or using a casting process often results in a greater variance in the final dimensions or surface of fabricated parts. Components may not fit together perfectly, limiting the function of the product.

CNC machining provides less variance and greater efficiency compared to other metal fabrication methods that involve more manual input. Computer-aided machines operate faster than human-operated machines while producing fewer errors, reducing material waste, and saving time.

Premium can produce parts by CNC Machining with tight tolerance+/-0.02mm and fine detail from a variety of metal or plastic materials.

Due to the subtractive nature of CNC, minor tool marks will be visible on the surface of the part after machining. A number of post-processing and finishing methods can be applied to improve the surface roughness, visual properties and wear resistance of the CNC machined parts.

Now we discuss the most common metal CNC finishes to help you select the most suitable surface finish for your application.

The available finishes are summarized below:

As machined

Sandblasting with Anodizing

Hard anodizing

Powder coating

Nitriding

Heat treatment

E-coating

Painting