With your specifications, our manufacturing engineers and production staff will produce your parts economically with reliable quality.

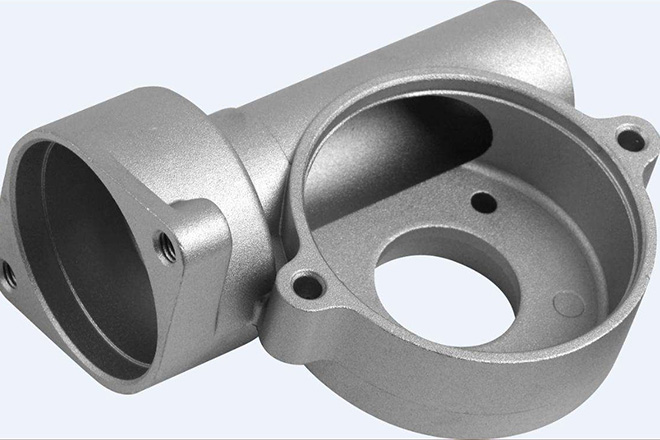

Complex shapes and thinner walls.

Excellent thermal and electrical conductivity.

Longer tool life without the need for constant maintenance.

Wide range of finishing options: almost any desired aesthetic characteristic and coating durability can be achieved.

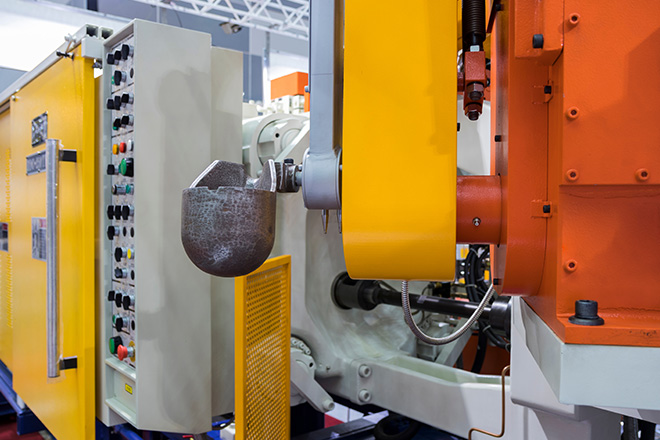

Faster production: rates of zinc die casting production are much faster than aluminum die casting or magnesium die casting.

Automotive

Electronics

Door & Window hardware

Industrial/Mechanical design

Common Zinc Alloys Application

Name: Door handle zinc die casting Material: Zamak2 Surface Finish: Chrome plating |  | Name: Bathroom Accessories zinc die casting Material: Zamak3 Surface Finish: Nickle Plating |  |

Name: Zinc die cast auto spare parts Material: Zamak5 Surface Finish: chrome plating |  | Name: Zinc die cast faucet Material: Zamak3 Surface Finish: Nickle Plating |  |

Material | Advantages |

Zamak2 | Highest strength and hardness of all Zamak alloys More excellent damping capacity and vibration attenuation than aluminum die cast alloys Higher creep performance than other Zamak alloys |

Zamak3 | Excellent balance of desirable physical and mechanical properties Superb castability Long-term dimensional stability Excellent finishing characteristics for plating, painting treatments |

Zamak5 | Higher strength than Zamak 3 More readily plated, finished than Alloy 3 Widely used zinc alloy in Europe |

Za8 | Excellent finishing and plating characteristics Highest creep strength of any zinc alloy Ideal for decorative applications |