We manufacture plastic extrusions in standard profiles, commodity plastics, engineering polymers, and coextruded and hollow profiles.

From standard shapes to multi-hollow shapes, you can rely on our rich experience to assure the parts will be delivered on time and at the right price. Whatever your plastic extrusion application, Premium can help.

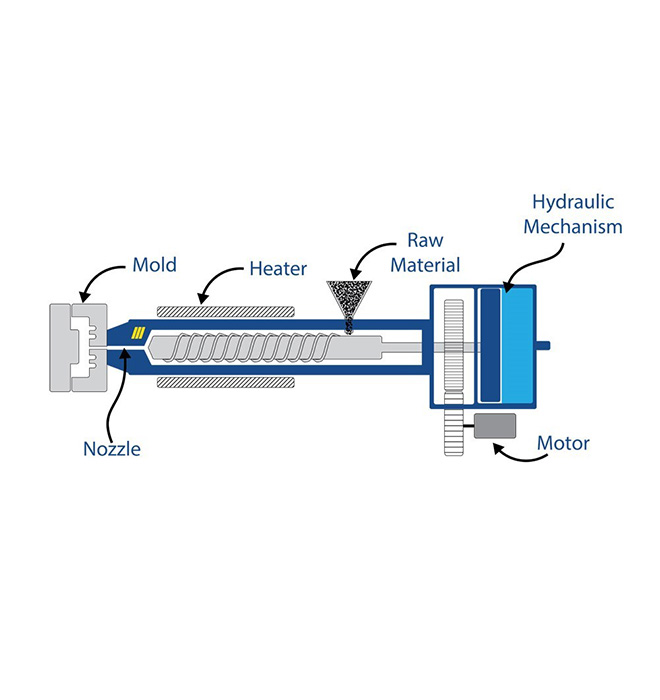

The first step is to melt and feed plastic material to the extruder. This plastic material can be, granule, pellet, powder or flake. The plastic is then slowly dissolved by the mechanical energy which is created. After melting, it is forced into a mold that forms a shape and hardens during cooling. Since plastics are great thermal insulators, cooling plastic can't be done very quickly.

Comparing to steel, steel conducts its heat away 2000 times quicker than plastic. In short, plastic extrusion is the process which transformed plastic into the shapes that can either be used the way it is produced or converted into usable products.

With our quality experience, our capabilities can help for your different plastic extrusion application.

Plastic Extrusions Capabilities

Plastic Extrusion & Molding

Custom Solid, Hollow & Multiple Hollow Shapes

Dual Durometer

Vacuum Calibration

Adhesive Application

Fabrication & Secondary

Rigid, Flexible & Elastomeric Compounds

There are a variety of materials we could process:

ABS | PVC | PP(Polypropylene) | PU(Polyurethane) |

PS(Polystyrene) | PC(Polycarbonate) | Nylon | Acrylic(PMMA) |

HDPE & UHMW Polyethylene | PETG | TPR/TPE/TPV | PTFE |