Premium solutions for magnesium die casting is to increase productivity and efficiency, Premium provide custom magnesium casting parts for various industries including automotive, medical, plumbing, watering, mining, food & dairy, machinery, petrochemical, electrical, energy and others. We also have technical experts and support engineers who can help you, from design to production.

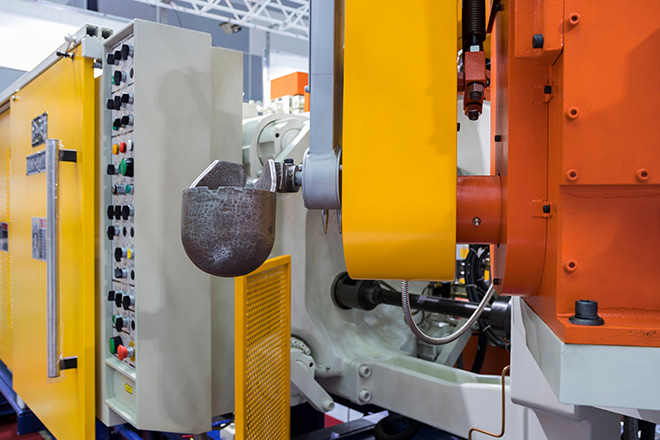

The Chamber of a hot-press chamber die casting machine is usually immersed in the liquid metal of the Crucible. In the process of die casting, the liquid metal enters the die chamber through the inlet when the injection punch rises: when the injection punch is pressed down, the liquid metal fills the die cavity through the nozzle along the channel, and after the liquid metal is cooled and solidified, the injection punch rises, at which point the mold is opened and the casting is taken out to complete a die casting cycle.

Light weight (75% lighter than steel, 33% lighter than aluminum) with high strength

Good thermal and electrical conductivity

Excellent for complex, thin-wall parts

Good finishing characteristics

Extended tool life

Specification | Photo |

Name: LED heat sink magnesium die casting Material: magnesium Surface Finish: Powder coating |  |

Name: auto part magnesium die casting Material: magnesium Surface Finish: sandblasting |  |

Name: magnesium die casting part Material: magnesium Surface Finish: Smooth |  |