Premium manufacture pressure die casted parts from 4 grams to 2 kilos, we provide them as cast, machined, polished, powder coated, or plated.

Brass die casting produces repeatable, complex shapes at competitive prices.

the major advantages of Brass die castings:

Temperature resistant

High electrical conductivity

Highly corrosion resistant

Easily polishing or plating

As a brass casting manufacturer, Premium provides all types of die casting that are designed according to the requirement of all the customers, we offer custom brass casting at our own metal casting foundry.

Brass is a very good metal casting with great results provided. The metal is an alloy of zinc and copper with a low melting point. Low melting point makes brass an ideal metal for casting, as it can be cast even in small furnaces. In addition, the hardness of brass can be increased or decreased by adding or removing alloys to meet different die-casting requirements.

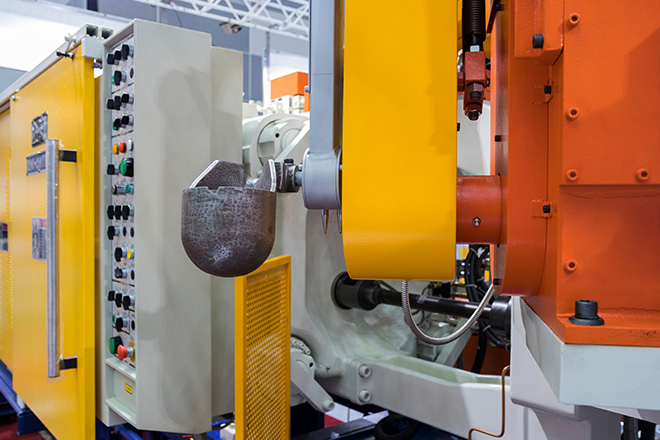

Brass casting is an automated process in which liquid melt is pressed into a die at high pressure (150 to 1200 bar) and at high filling speeds (up to 540 km/h). Alloys with a low melting point are usually used. This casting process is particularly suitable for parts serialization and mass production because, unlike sand casting, permanent metal molds are used after casting and do not have to be destroyed. Large and complex parts with low wall thickness can be produced.

Specification | Photo |

Name: Water pump parts brass die casting Material: Surface finish: Plating |  |

Name: Water meter body brass die casting Material: brass Surface finish: Blasting |  |

Name: Brass die casting fitting parts Material: brass Surface finish: Elcetroplating+baking varnis |  |