Premium advanced technologies for sheet metal press die can rapidly create and handle complex sheet metal press parts. We have tooling for presses up from 15-400 tons in-house, in accordance with ISO compliant, our tool and die manufacturing operations hold tolerances down to +/-0.025mm.

Sheet Metal Punch is done through a punching press, changing the shape of the metal, forming and cutting it. When metal passes through a press, it is cut into predetermined shapes.

Sheet metal punch dies to use a cold-forming process that makes use of dies and sheet metal press forming to transform sheet metal into different shapes.

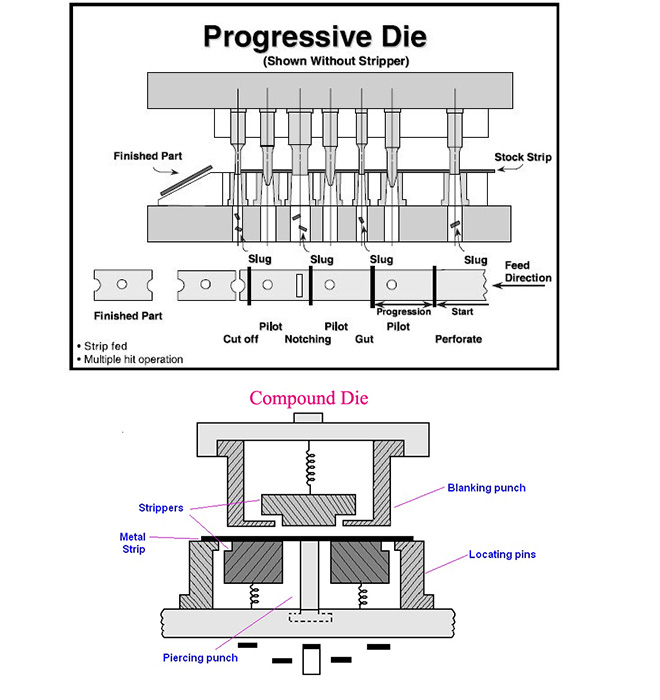

There are several components for a die to set. These include punch plate, guide, setting block, blank punch, pierce punch, stripper plate, pilot, blanking dies.

Sometimes operations of die sets are not limited to one specific die. Some dies may use multiple operation types, including:

○ Bending ○ Planking ○ Broaching ○ Extruding

○ Cold forming ○ Roll forming ○ Hydroforming

○ Piercing ○ Coining ○ Compound operations

○ Curling ○ Cut off ○ Drawing ○ Shaving

○ Slagging ○ Trimming

Premium offer you low volume and high volume sheet metal fabrication from small to large parts, and complex project to further enhance our precision forming capabilities.

Our Application Include:

Automotive

Control and automation systems

Electronic communication

Enclosures

Infrared Radiant Heaters

Doors

Assemblies

Lighting

Body panels