CNC Precision Machining is a process to remove material from an object to create a smaller, finished product utilizing cutting machines, software applications, and human engineering to meet very exacting specifications and close tolerance finishes. It usually refers to CNC turning, CNC milling service, Multi-Spindle machining or electrical discharge machining. Quality precision machining requires the ability to follow extremely specific blueprints, these blueprints must be adhered to with great detail to ensure that a product retains its integrity.

CNC precision machining is very efficient, cost effective, simple and very safe to use. Premium provide precision machining work by our advanced 3 axis & 4 axis & 5 axis CNC machines and 19 years experience engineers to ensure all the parts are highly performed.

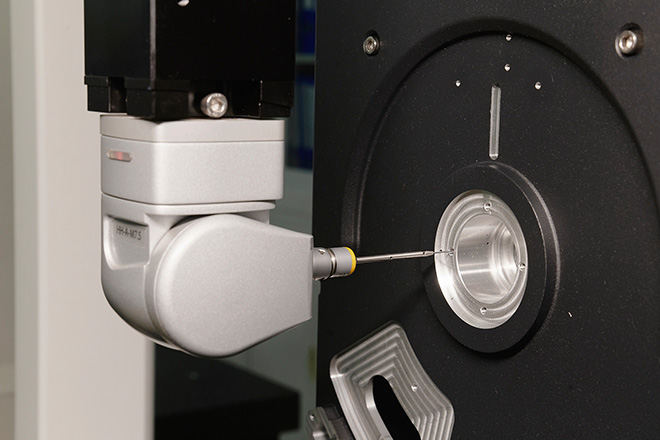

Premium provides 5 axis machining service, 5 axis CNC machine move a workpiece along five different axes concurrently. This requires high-level precision machining of very complicated parts that are far beyond other machining technologies can provide.

Five-sided milling also produces a smooth surface finish which is necessary for many manufacturing applications. In spite of its utilization of advanced technology, 5-axis CNC machining offers premium results at an affordable price point and fast turnaround.

Here are standard tolerances of the parts produced by Premium Rapid and Mold, tolerances up to ± 0.01mm are available upon request and less than ± 0.01mm tightest tolerances are examined on a case by case basis with your technical drawings.

Tolerance Level | Dimension Range | ||||||

Specifications | <<2000mm, >1000mm | <<1000mm, >400mm | <<400mm, >120mm | <<120mm, >30mm | <<30mm, >6mm | <<6mm, >3mm | <<3mm, >0.5mm |

Tolerance Standard | |||||||

F | ±0.5mm | ±0.3mm | ±0.2mm | ±0.15mm | ±0.1mm | ±0.05mm | ±0.05mm |

M | ±1.2mm | ±0.8mm | ±0.5mm | ±0.3mm | ±0.2mm | ±0.1mm | ±0.1mm |

C | ±3mm | ±2mm | ±1.2mm | ±0.8mm | ±0.5mm | ±0.3mm | ±0.2mm |

V | ±6mm | ±4mm | ±2.5mm | ±1.5mm | ±1mm | ±0.5mm | – |