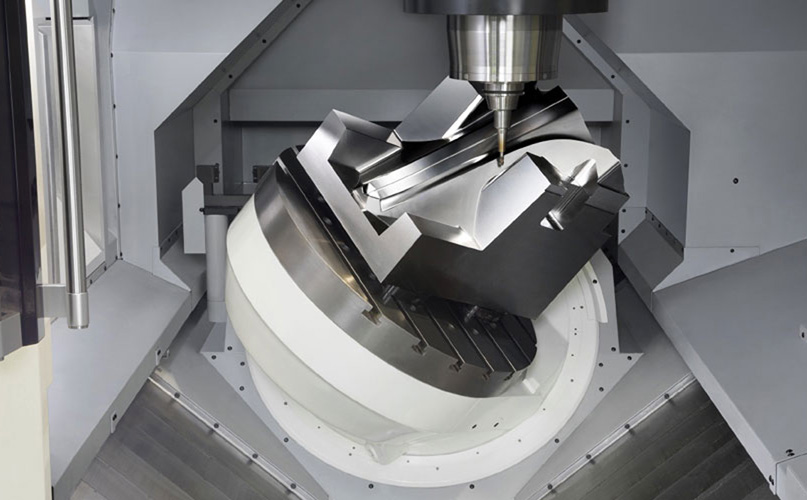

CNC milling belongs to the machining process, it can be used to create complex 3D shapes or to apply a machined feature or surface to parts for both plastics and metals. The machinery is the most important element for the process of milling, Premium precision machine inc uses multi-axis milling machines includes the 3&4&5 axis that creates many different parts types and features of complex geometries. That means can be slots, angled shapes, holes, curves, circulars, and channels.

CNC milling is a certain type of CNC machining services, a machining process suitable for high accuracy and high tolerance parts in prototype and small to medium production runs. Some milling machines can achieve tolerances of up to and greater than +/- 0.005mm. The versatility of the milling process allows it to be used in a wide range of industries and for a variety of part features and designs, including slots, chamfers, threads, and pockets. The most common CNC milling operations include Face milling, Angular milling, Form milling, Plain milling.

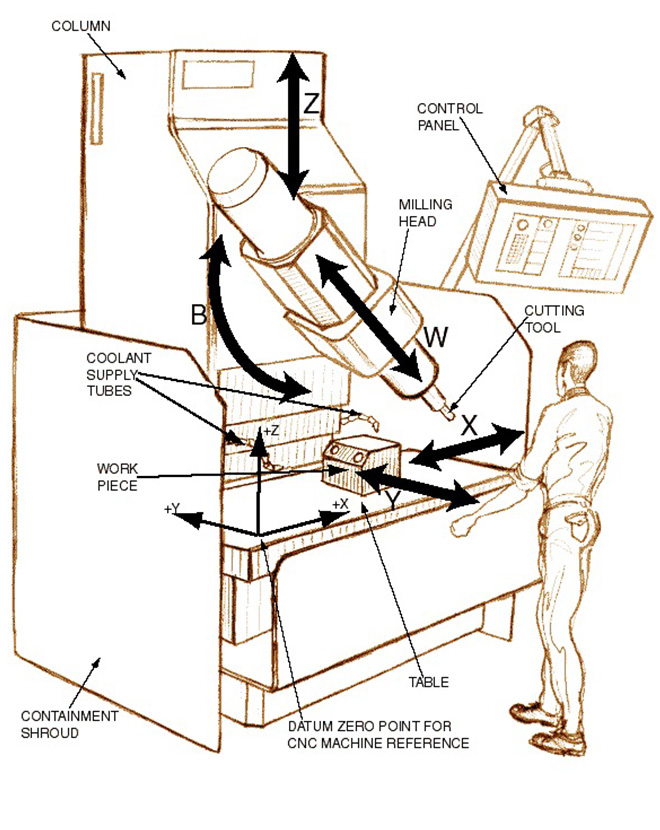

CNC milling is often grouped by the number of axis, from 3 to 5 axis. Each axis is labeled using a specific letter. For instance, X and Y axis stands for the horizontal movement of the mill's workpiece. The Z-axis designates vertical movement and the W axis represents the diagonal movement across the vertical plane.

First of all, to understand the difference between CNC lathes and milling machines, simply said, the CNC lathe is to machining the round parts, milling machine is to machining plane parts, the difference between CNC turning and milling is which part actually moves – the machine itself or the raw material. CNC milling is part rotation, CNC milling is tool rotation, the part does not rotate.

Although this is quite simplistic, these processes are far more complex than you can see. Here are some more ways to distinguish between CNC turning and milling:

Purpose: CNC turning is mainly used for machining cylindrical or conical surfaces, while CNC milling is more suitable for machining flat and irregular surfaces.

Tool features: CNC turning is single point cutting tool, and CNC milling tools is multi-point cutting tools.

Chips: CNC turning can produce discontinuous, continuous, and chips, while CNC milling always produces discontinuous chips.

Cutting: CNC turning involves continuous cutting in which the tool is in continuous contact with the workpiece. CNC milling uses intermittent cutting in which the cutting teeth are continuously meshed and separated from the raw material.

Whether you are looking for CNC turning, milling, or any other precision engineering services, you need a supplier that you can trust. The parts you need must be of the highest quality and built to stand the test of time.

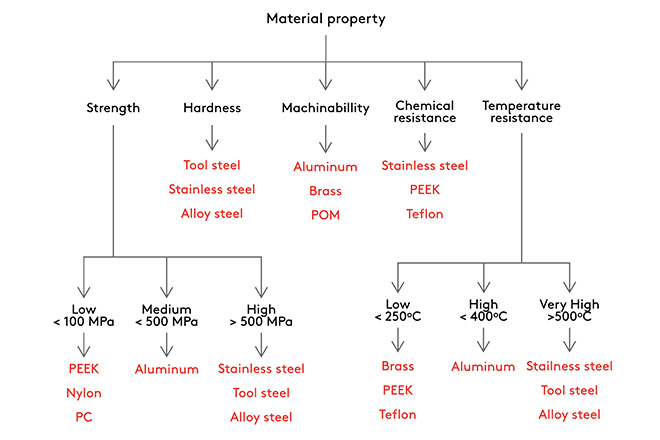

CNC precision milling and machining are indeed common manufacturing processes, offering rapid production with minimal human input. Aluminum is most common in CNC milling processes due to its excellent machinability, workability and versatility. It is generally able to be machined quicker than other materials. Parts made from aluminum form a protective layer when exposed to the environment, which leads to extra strength and corrosion resistance. Except for aluminum, steel and stainless steel are engineered for premium machinability, steel is typically used for parts that require enhanced formability and stronger welds. The best applications of this material include commercial products, parts that require strong welds, gears and shafts, along with other high stress applications. Stainless steel can be heat treated and supply corrosion resistant properties and with a superior strength-to-weight ratio that is commonly used in the automotive and aerospace industry.

There are lots of options of materials for CNC milling technology, please see the brief introduction below and check which material you should choose for your application.

Material | Grade | Hardness | Strength | Machinability | Typical applications |

Aluminum | 5083 | Low | Medium | ★★★★★ | Marine applications, Construction, Pressure vessels |

6061 | Medium | Medium | ★★★★★ | General-purpose, Aircraft components, Automotive parts, Bicycle frames, Food containers | |

6082 | Medium | Medium | ★★★★★ | General-purpose, Automotive parts, Food containers | |

7075 | Medium | High | ★★★★ | Aircraft & aerospace components, Automotive parts, Marine applications, Sports equipment | |

Stainless Steel | 303 | High | High | ★★★ | Aircraft components, Machine parts, Nuts, bolts, gears, bushings |

304 | Medium | High | ★★ | General-purpose, Medical devices, Food industry, Marine applications, Chemical processing | |

316 | Medium | High | ★★ | Food preparation equipment, Marine applications, Architecture, Surgical implants, Chemical containers | |

Mild Steel | 1018 | Medium | Medium | ★★★ | General-purpose, Machinery parts, Jigs & fixtures |

1045 | High | Medium | ★★ | General-purpose, Machinery parts | |

A36 | Medium | High | ★★★ | Construction, Machinery parts, Jigs & fixtures | |

Alloy Steel | 4140 | High | Medium | ★★ | General-purpose, Machinery parts, Tooling |

4340 | High | High | ★★ | Aircraft landing gear, Power transmission, Tooling | |

Tool Steel | D2 | Very High | High | ★ | Cold-working tooling, Dies & stamps, Cutting tools & knives |

A2 | Very High | High | ★ | Cold-working tooling, Dies & stamps | |

O1 | Very High | High | ★ | Mechanical parts, Valves & nozzles, Architecture | |

Brass | C36000 | Medium | Medium | ★★★★★ | Mechanical parts, Valves & nozzles, Architecture |

Material | Strength | Operating temperature | Machinability | Typical applications |

Polycarbonate (PC) | High | Up to 120℃ | ★★ | Architecture, Automotive, Electronic enclosures, Food containers |

ABS | Medium | Up to 60℃ | ★★★ | Automotive, Electronic enclosures, Pipes & fittings, Consumer products |

Nylon | High | Up to 100℃ | ★ | Automotive parts, Mechanical parts, Fasteners |

POM | Medium | Up to 82℃ | ★★★★ | Mechanical parts, Electronic enclosures, Bushings & fittings |

PTFE(Teflon) | Low | Up to 260℃ | ★★★★ | High-temperature applications, Chemical processing, Electronic enclosures, Food processing |

PEEK | High | Up to 260℃ | ★★ | Medical applications, Chemical processing, Food processing, High-pressure valves |

HDPE | Low | Up to 80℃ | ★ | Chemical containers, Pipes & fittings, Consumer products |