2K is well known as 2 shot injection molding or two colour injection moulding, consists of two different plastics or two different colors of one plastics into an end product by means of one injection molding process.

Premium is an industrial machining inc that has manufactured parts using the 2K injection moulding process for more than 20 years. The 2k injection molding process enables several functions to be integrated into an injection molded part. Due to the chemical bond between the different materials, excellent adhesion is achieved, without the thermoplastic part requiring chemical pre-treatment. two colour/ 2K injection moulding component technology is also ideal for parts with large batches.

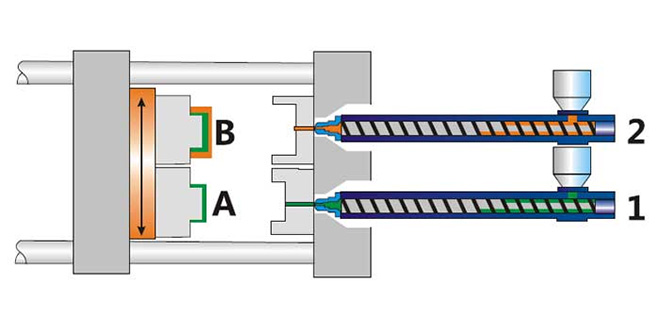

2K injection moulding, sometimes know as double injection, two color injection molding, or 2 shot molding, is an innovative manufacturing process used to produce complicated molded parts from two different materials into the multi-chambered mold.

2K injection moulding perform in one machine which is programmed to perform two injections in one cycle. In the first cycle, a nozzle injects plastic into a mold. The 2k plastic injection moulding is then rotated automatically and another type of plastic is injected from a second nozzle into the mold.

No secondary processing and assembly steps

Excellent adhesion to the plastic part

Low handling

Quick cycle times

High degree of automation

Stable production processes

Economical cost

As one of the professional injection mold components suppliers, Premium has advanced machines that take 2K injection molding/two colour injection moulding.

The 2k injection moulding allows us to integrate multiple properties into one product: for instance, layered products, combinations of hard and soft plastic for making different color combinations.

Two color injection molding optimizes co-polymerization of hard and soft materials to create a perfect bond with production and feature advantages for a single part. Almost all industries can use two colour injection moulding for a variety of product designs. The 2k injection also allows for moulding using clear plastics, colored graphics, and stylish finishes which improves customer's product functionality and marketplace value.

The technology 2K injection molding makes it possible to produce a complete product so that this part does not need further secondary processing and assembly steps. That means gains in the quick cycle time, a constant process, a higher degree of efficiency and the avoidance of manual operation, you can save cost also save considerably on costs with two colour injection moulding.

Plastic Material | PP, PP+20% GF, PA6, PLA, AS, ABS, PE, PC, PVC, POM, PET, PS, TPE/TPR etc |

Mold Material | 718H, P20, NAK80, S316H, SKD61, etc. 20~60 HRC |

Mold Base | HASCO, DME, LKM, JLS standard |

Mold Runner | Cold runner, hot runner |

Mold Cold Runner | Point way, side way, follow way, direct gate way, etc. |

Mold Hot Treatment | Nitridation, tempering, etc. |

Mold Surface | texture, EDM, high gloss polishing |

Mold Cooling System | water cooling or Beryllium bronze cooling, etc. |

Lead time | 25-60 days |